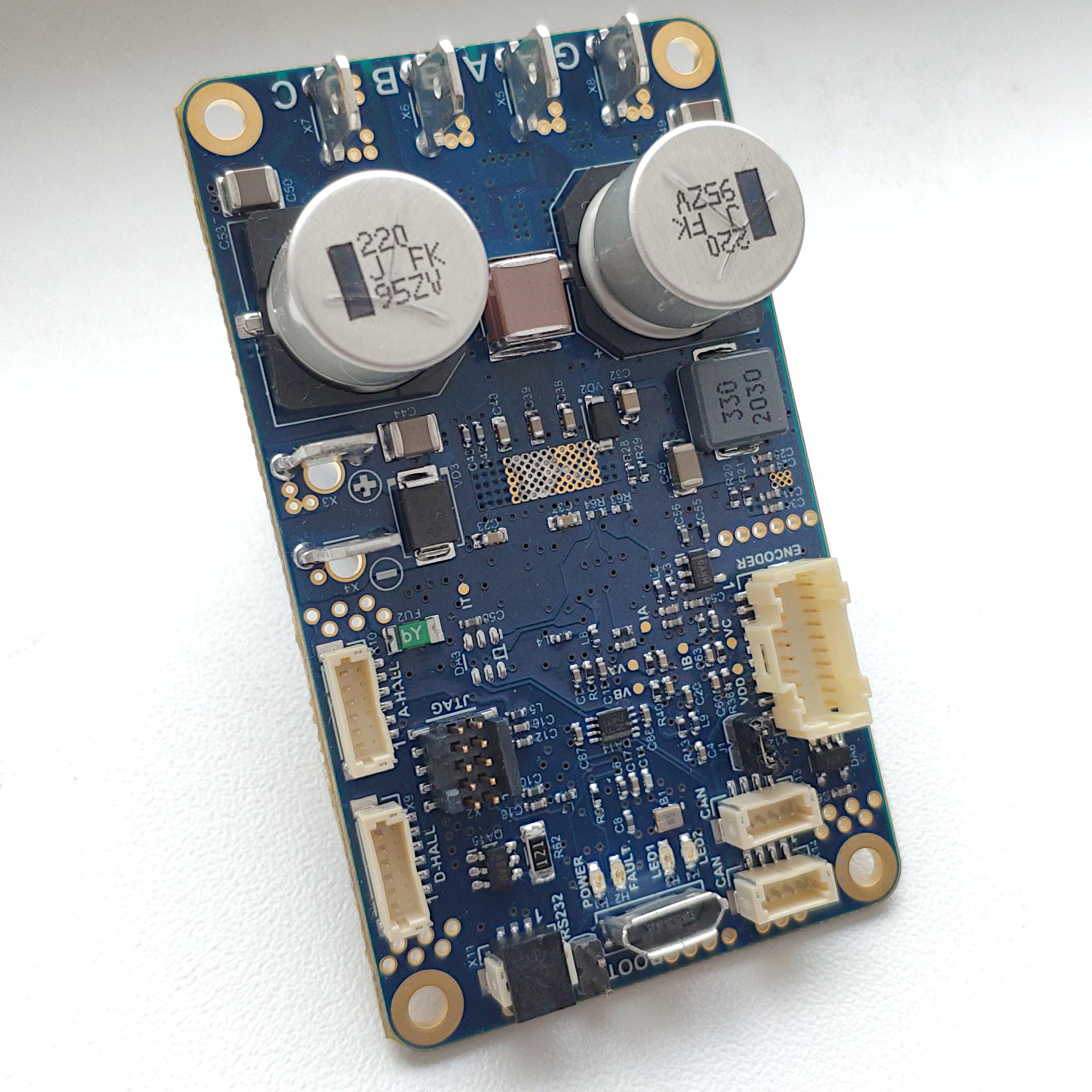

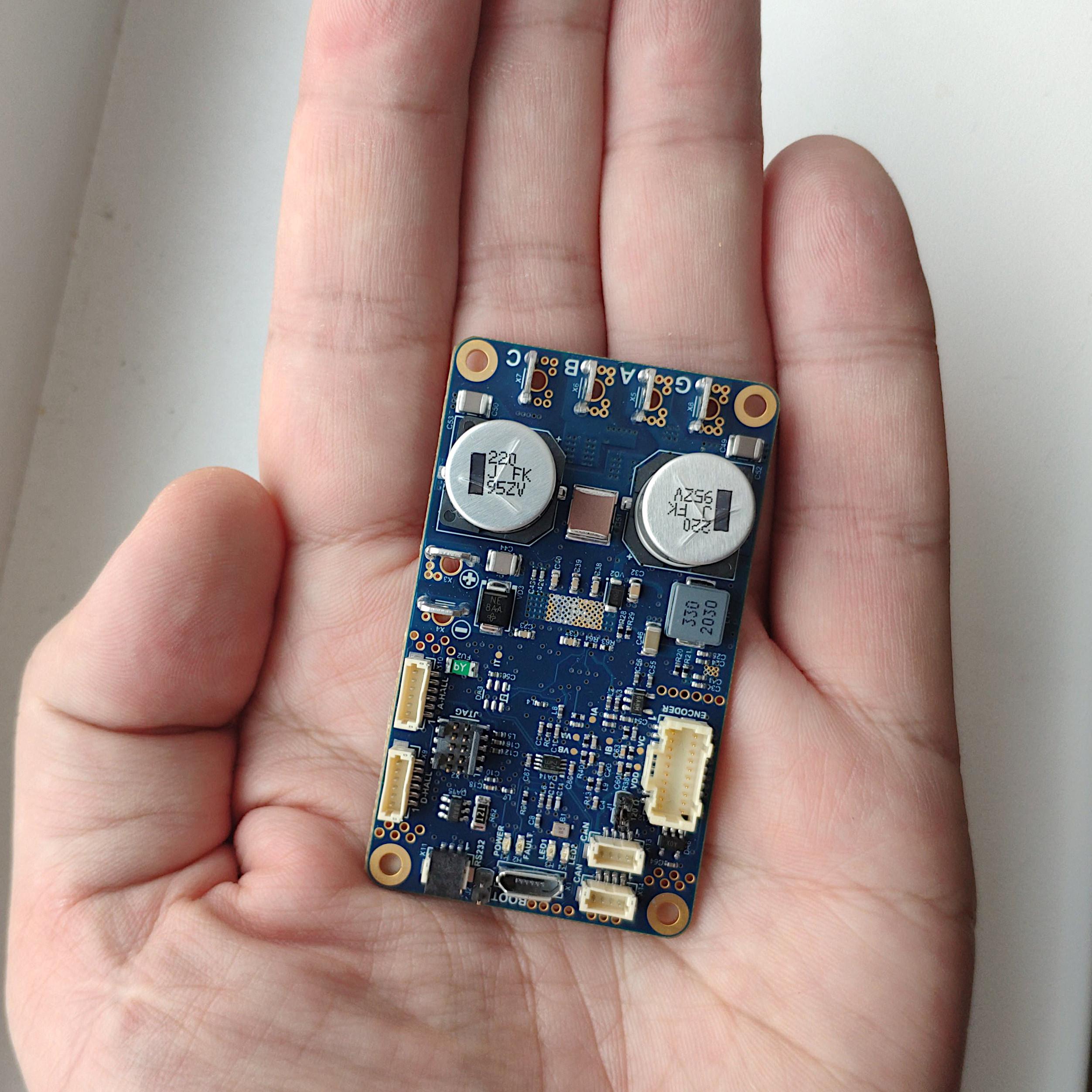

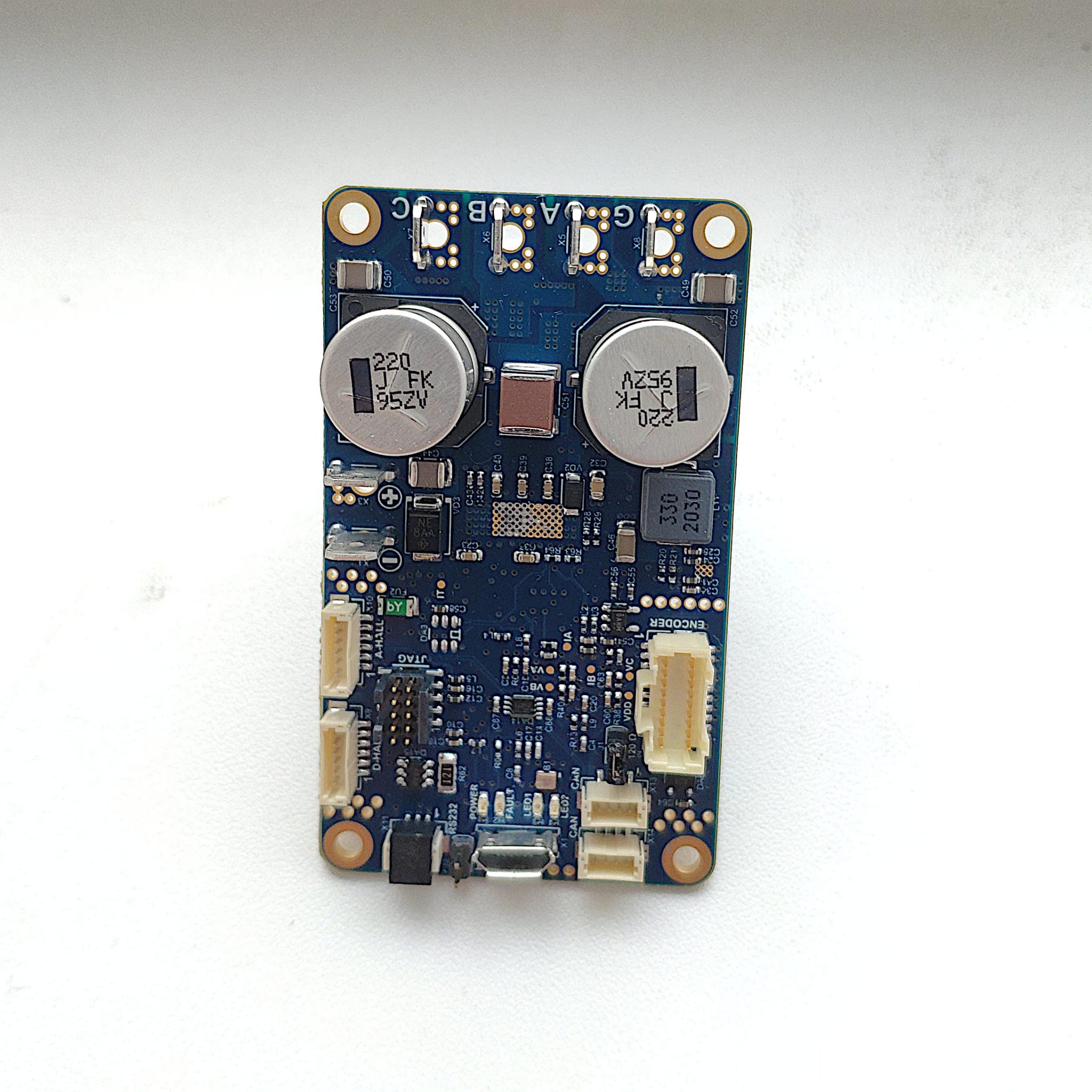

Servosila SC-25R Brushless/Brushed Motor Controller (rectangular shape)

$199.00

Servosila SC-25R Brushless/Brushed Motor Controllers are miniature electronic units that provide high-precision control over a wide range of mechanisms actuated by brushless or brushed electric motors (PMSM, BLDC, Direct Drive, Gimbal, Brushed) of any manufacturer. The controllers turn electric motors into computer controlled traction drives, high-precision direct drives, or servo drives when (optionally) paired with absolute position encoders (BISS-C, SSI, SPI, PWM or Quadrature) of any manufacturer.

Up to 25A of phase-to-phase current, and up to 32bits of angular precision are provided. The input voltage is 7V to 60V DC. The servo drives are suitable for high-precision applications such as lithographic machines or tracking telescopes.

The electronic units feature a microprocessor chip, a set of absolute encoder interfaces for shaft position measurements, a firmware implementation of advanced motion control algorithms that operate in a closed loop fashion, as well as CANbus/CANopen and USB interfaces for receiving commands from a control computer/PLC and sending back telemetry.

You may also like…

-

Cable assembly for connecting Hall sensors to Servosila SC-25 controllers

$9.99 Add to cart -

CAN bus cable assembly for interconnecting Servosila SC-25 controllers

$9.99 Add to cart -

Cable assembly kit for connecting encoders to Servosila SC-60 and SC-25 controllers

$14.99 Add to cart -

Servosila SC-25C Servo Drive (circular shape) [NRND]

$219.00 Add to cart -

Power & Phase connectors for Servosila SC-60 and SC-25 controllers

$5.99 Add to cart